Updated : May 31, 2017

FPG-LT Coffee Bag with Gas-filled Overwrap Packaging Machine

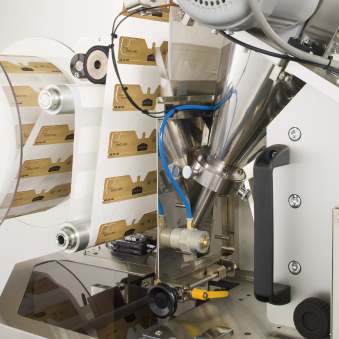

Coffee Bag with Gas-flled Overwrap Packaging Machine

This is the upgraded model of the FPG-T1,

which is our standard drip coffee bag packaging machine.

●The new design is easier to maintain and operate.

●Multi-functional machine with the ability to pack drip coffee bags and tea bags.

●Nitrogen gas-filling prevents oxidation. Every single sachet can keep the taste and aroma fresh right before drinking.

(Nitrogen Gas-Filling Device is included with Standard Specification)

●Capacity up to 60 bags/min.

![]()

Auger Filler (Optional)

Easy Maintenance

Improved User-Friendliness

| Inner Bag Packaging Section | Packaging Method | 3-Side Ultrasonic Sealing and Cutting |

| Measurement Method | Standard: Slide Doser Weighing Option: Load-Cell Weigher, Auger Filler |

|

| Packaging Materials | Nylon, Non-Woven Fabric, and any suitable filters for ultrasonic sealing | |

| Filter Width | 120–200 mm | |

| Bag Size | Rectangular: 45–65 (W) x 60–90 (L) mm Drip bag: 90 x 65–83 mm |

|

| Overwrapping Section | Packaging Method | 3-Side Heat Sealing |

| Packaging Materials | Laminated Film (PP, PE, etc.) | |

| Film Width | 140–220 mm | |

| Overwrap Size | Overwrap (for Rectangular): 70–100 (W) x 85–120 (L) mm Overwrap (for Drip Bag): 100–110 (W) x 120–135 (L) mm |

|

| Capacity | Max. 60 bags/min. | |

| Dimensions | 1,340 (W) x 1,140 (D) x 2,915 (H) mm | |

| Weight | 880 kg | |

| Power Supply * | 3-Phase / 200 V / 2.2 kW | |

| Compressed Air * | 320 L/min. (6 bar) | |

| CE Marking ** | Optional | |

** Fail-safe design based on CE directive.

Option

●Weighing System (Load-Cell Weigher, Auger Filler etc.)

●Poking Device for Sub-Hopper

●Slide Doser Vibrator

●Chute Knocking Device

●Various Size of Chutes (120 mm, 140 mm, 160 mm, 180 mm etc.)

●Discharge Device of Defective Product

●Date Printer

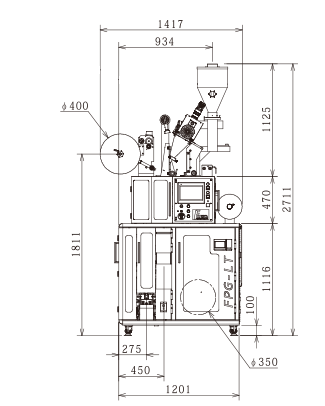

Layout

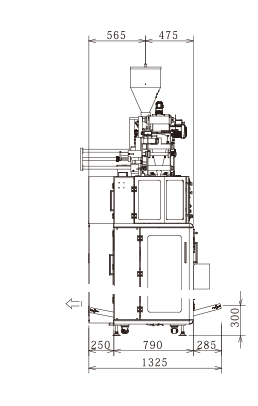

■FPG-LT with Auger Filler (Optional)

Righit side view

Front view