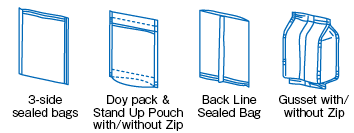

| Packaging Method | 3-Side Heat Sealing |

| Packaging Materials | Paper, Laminated Film or Non-Woven Fabric and any suitable materials for heat sealing |

| Measurement Method | Standard: Rotary Doser Weighing Option: Load-Cell Weigher, Auger Filler |

| Filling Volume | 10–35 CC (with Standard Doser) (Depends on package size and measurement method) |

| Feeding Pitch | 55–150 mm |

| Filter Width | 80–240 mm by 20 mm *need to change chute and sailor |

| Capacity | 30–80 bags/min |

| Dimensions | 1,275 (W) x 855 (D) x 1,810 (H) mm |

| Weight | 450 kg |

| Power Supply * | 3-Phase / 200 V / 4.0 kW |

| Compressed Air * | 300 L/min. (6 bar) |

| CE Marking ** | Not Available |

** Fail-safe design based on CE directive.