Updated : September 24, 2015

FP-100S Tea Bag Packaging Machine

Tea Bag Packaging Machine

High Production Rate

●Beautifully shaped tea bag by ultrasonic sealing & cutting.

●Easy to produce tea bags by using pre-tagged filter material.

●Able to switch between triangular and rectangular shape tea bags with one button.

●Meets CE safety requirements for customers who need a CE. certified machine.

●Capacity up to 80 bags/min.

![]()

| Packaging Method | 3-Side Ultrasonic Sealing and Cutting |

| Measurement Method | Standard: Slide Doser Weighing Option: Load-Cell Weigher, Auger Filler |

| Packaging Materials | Nylon, Non-Woven Fabric, and any suitable filters for ultrasonic sealing |

| Filter Width | 120–180 mm |

| Tea Bag Size | Triangular: 50–80 mm (each edge) Rectangular : 40–80 (W) x 50–80 (L) mm |

| Capacity | Max. 80 bags/min. |

| Dimensions | 820 (W) x 970 (D) x 2,255 (H) mm |

| Weight | 450 kg |

| Power Supply * | 3-Phase / 200 V / 2.5 kW |

| Compressed Air * | 340 L/min. (6 bar) |

| CE Marking ** | Standard |

** Fail-safe design based on CE directive.

Option

●Weighing System (Load-Cell Weigher, Auger Filler etc.)

●Poking Device for Sub-Hopper

●Slide Doser Vibrator

●Chute Knocking Device

●Multiple Feeding Device for Long Bags

●Acrylic Cover for Packaging Material Roll

●Various Size of Chutes (120 mm, 140 mm, 160 mm, 180 mm etc.)

Layout

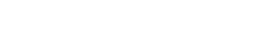

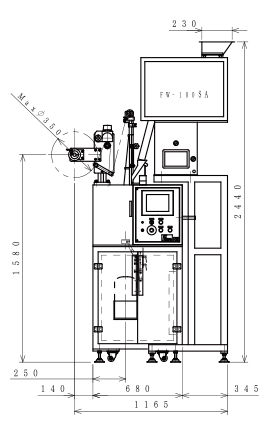

■FP-100S with Load-Cell Weigher, FW-Series (Optional)

Front view

Right side view

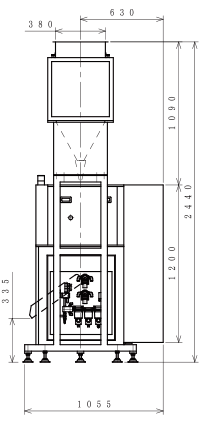

■FP-100S in Standard Specification

Front view